Your partner

in dry ice cleaning.

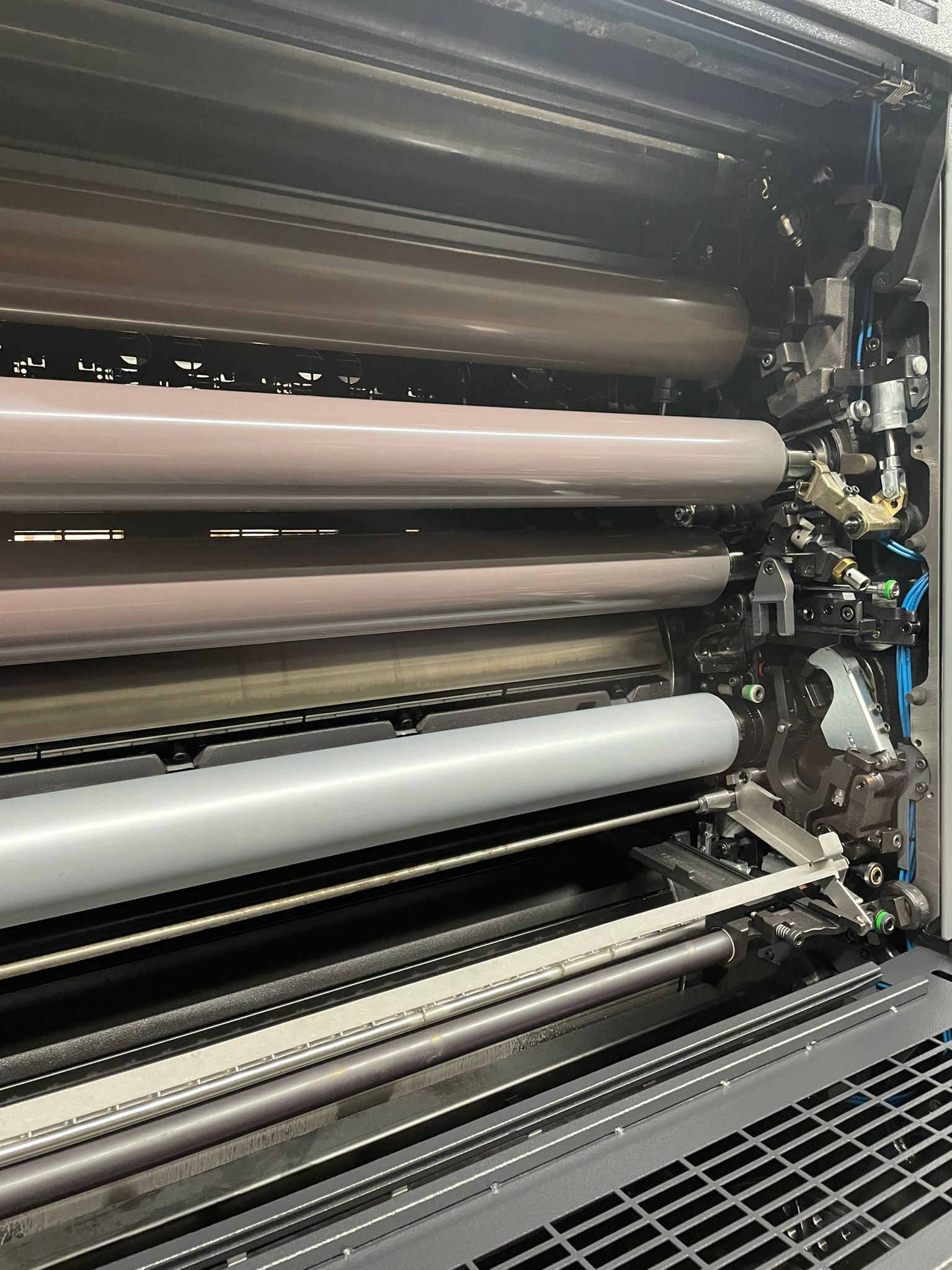

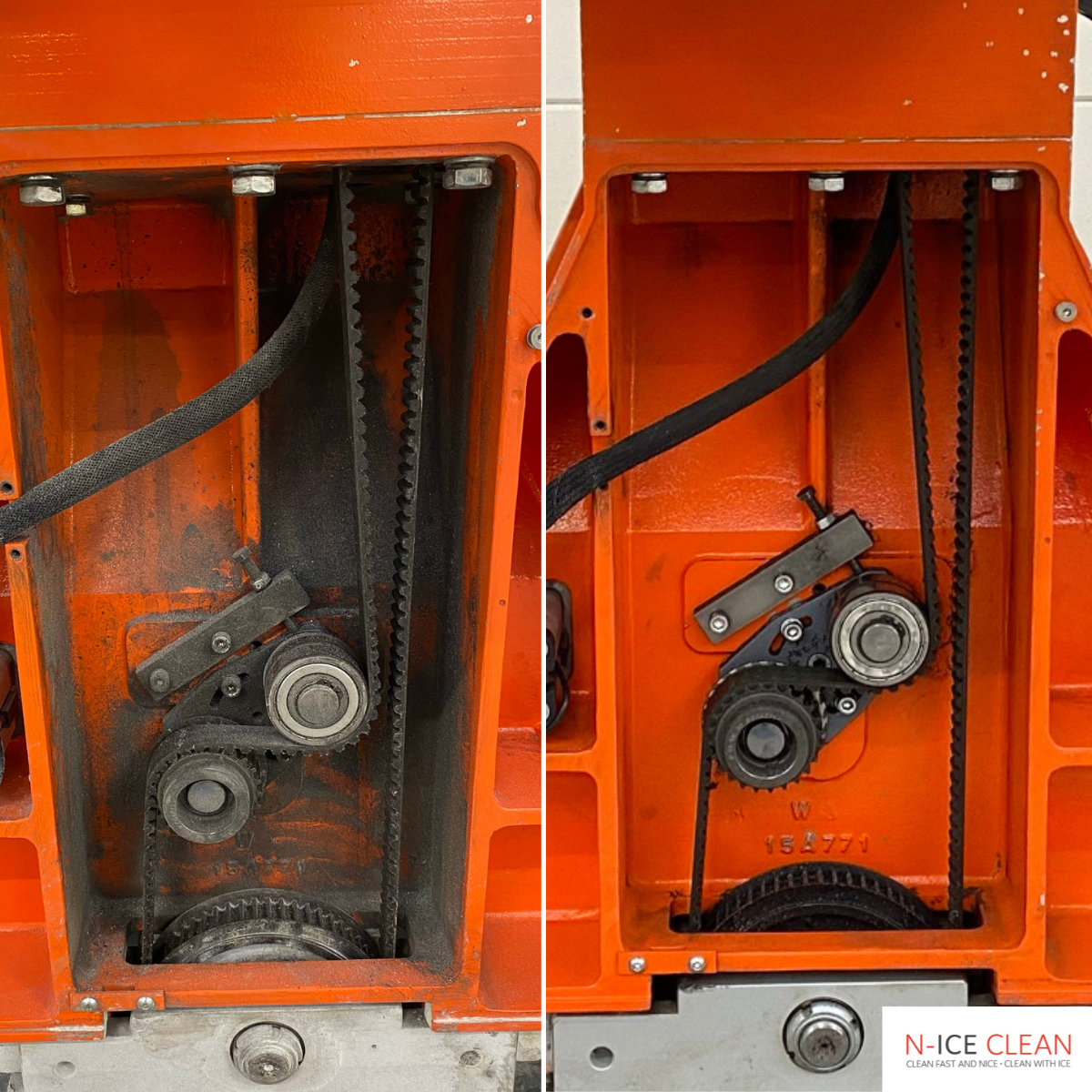

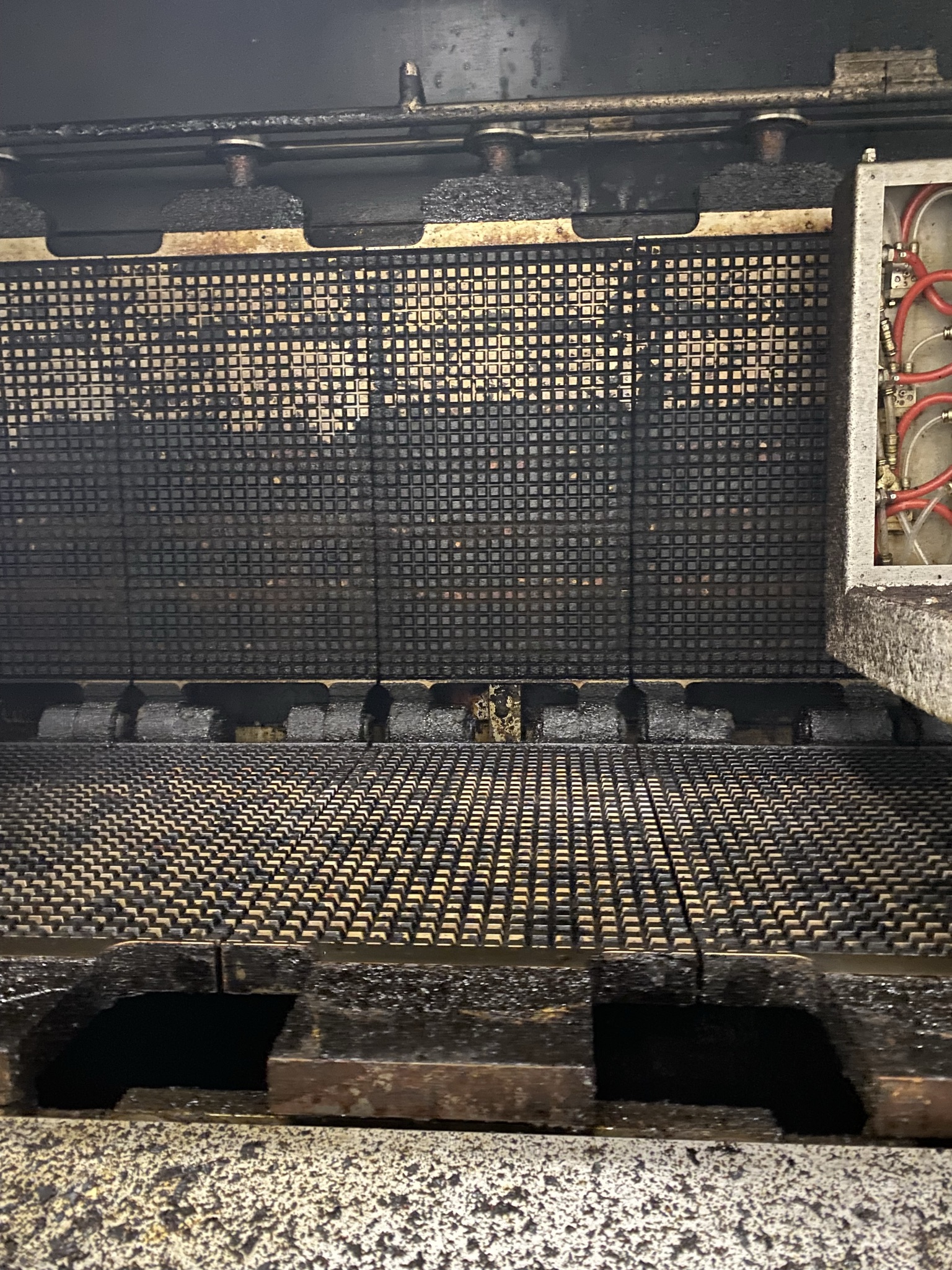

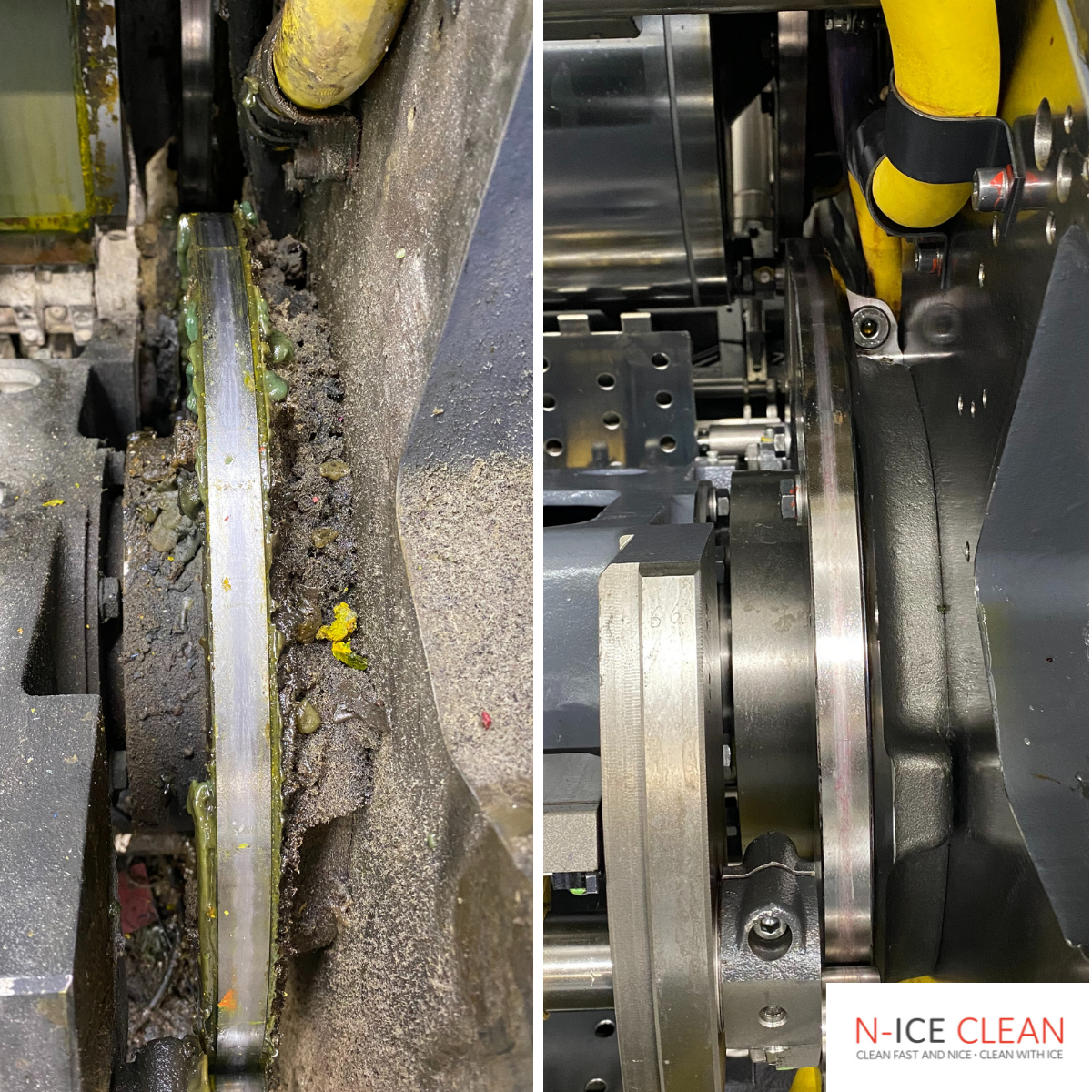

N-Ice Clean is specialised in the cleaning of printing presses using CO2 dry ice. This way of working is very efficient and environmentally-friendly

You can find us...

N-ice clean operates in several sectors

Besides specialising in cleaning printing presses, we also operate in the medical and food sectors.

in the

Medical sector

in the

graphics sector

in the

Food sector

You can find us...

N-ice clean operates in several sectors

Besides specialising in cleaning printing presses, we also operate in the medical and food sectors.

Food sector

graphics sector

Medical sector

How it works

Cleaning processes

Pyrolysis oven

We clean the parts thermally in our pyrolysis oven. Both aluminium and iron parts are perfectly stripped of their coatings. Because the pyrolysis process takes 12 hours and due to a slow warming up, the parts do not deform as it might be the case with conventional ovens.

The pyrolysis oven process is often used to remove a coating in the painting industry. Metal parts with silicone can also be pyrolyzed. The silicon is converted into dust.

Cleaning processes

Ultrasonic

We clean chemically several parts with our different ultrasonic baths. The combination of the right chemistry, the right temperature and ultrasonic vibrations ensure the parts looking as brand-new ones.

These clients went before you.

These clients went

before you.

N-ICE CLEAN has already helped many clients in various sectors. All have one thing in common: they are satisfied. Do you have a challenging project for us? Get in touch with us.

N-ICE 80°

Dry ice is CO2 in

solid form, with a temperature of

-78,5 °C.

Dry ice is CO2 in solid form, with a temperature of -78,5°C.

Purposes

- Refrigeration/Freezing on location without any electricity

- Rapid freezing

- Transport refrigeration

- Emergency refrigeration

- Extending the storage life of food

- Inertisation

- Eliminating rodents and other vermin

- Cold chain guarantee

Properties

- High cooling capacity

- Odourless and tasteless

- Free of bacteria and germs